We plan –

you produce!

With planning flex, your production planning becomes simpler, more efficient and cost-saving. Our service adapts flexibly to your needs, automates important planning processes and optimises the use of resources. This gives you full control and transparency without additional effort - ideal for companies that want to sustainably increase growth and efficiency.

-

-

-

-

-

Planning runs

-

Planning the machinery

-

Midnight Service

-

-

Basic BDE software

-

-

-

-

-

-

-

Advantages of planning flex

![]()

Mastering shortage of skilled labour

![]()

Reduced

operating costs

![]()

Increased

efficiency

![]()

Focus on

core business

![]()

Fast

implementation

planning flex offers a flexible and cost-effective solution for your production planning. You only pay for the planning runs you use, without having to invest in expensive software. having to invest in expensive software. With customisable plans that can be scaled at any time, we adapt to your individual requirements. By using experienced experts and state-of-the-art planning software, your production processes are efficiently optimised, resulting in reduced downtimes and better use of resources. and better utilisation of resources. Regular reports and transparent communication ensure full control. Whether basic, premium or enterprise plan, planning flex offers the right solution for any size of company.

About planning flex

The planning flex team takes care of the entire production planning for you - without the need for additional personnel and/or expensive software. With our specially developed service, our experienced experts optimise and plan your production processes so that you can concentrate fully on your core strategic tasks. can concentrate fully on your strategic core tasks. Our solution offers full transparency, flexibility and scalability. While we take care of the smooth organisation, you increase your efficiency and reduce unnecessary costs. This turns production planning into a competitive advantage - without any additional personnel costs.

Planning flex makes your production planning easier, more efficient and completely stress-free. Our service is specially designed to help companies optimise to help companies optimise their production processes - without the need to hire additional staff. Whether you are a small company or a medium-sized production company, planning flex adapts flexibly to your needs and helps you to manage the entire planning process from capacity utilisation to resource management. capacity utilisation to resource management. We take care of everything for you.

Thanks to our innovative solution, you no longer have to worry about manual and time-consuming planning tasks. planning flex takes over many of these processes, so you can save time and money while increasing the efficiency of your production.

By planning all relevant production processes (in real time if required), we maintain an overview for you and can react flexibly to changes. planning flex offers you full transparency of your processes and enables you to make data-based decisions to continuously improve your production.

Our expert team is also on hand to help you with any problems. Rely on a solution that not only simplifies your planning, but also offers you also helps you to remain competitive.

What?

- Complete production planning: Takeover of the entire production planning by planning flex. Use of an internally developed tool that has been tried and tested over many years by planning experts.

- Goal: Planning and optimisation of production processes.

- Focus on core competences: Companies can concentrate on their main task, as we take care of all the planning.

- Innovative planning: Specially developed for efficient and automated management of production processes.

Why?

- Cost efficiency: Reduce costs by dispensing with additional planning software and only paying for the planning runs you actually need.

- Mastering the shortage of skilled labour: Outsourcing means that the shortage of skilled labour is no longer a challenge for your production planning.

- Flexibility and customisability: Choose the plan that best suits your needs and scale it easily as your requirements grow.

- Expertise and quality: Benefit from an experienced team that uses proven methods and advanced planning software to optimally support your production.

How?

- Fast implementation: The implementation is simpler and takes less time to integrate than an extensive software roll-out.

- Automated planning: planning flex takes over the management and optimisation of your production processes and adapts flexibly to changes and new requirements.

- Regular reports: You receive detailed reports and updates on an ongoing basis as required, which create transparency and help you to make targeted optimisations.

- Expert support: Our team of experienced planning experts is on hand to answer your specific questions about customisation.

What our customers say:

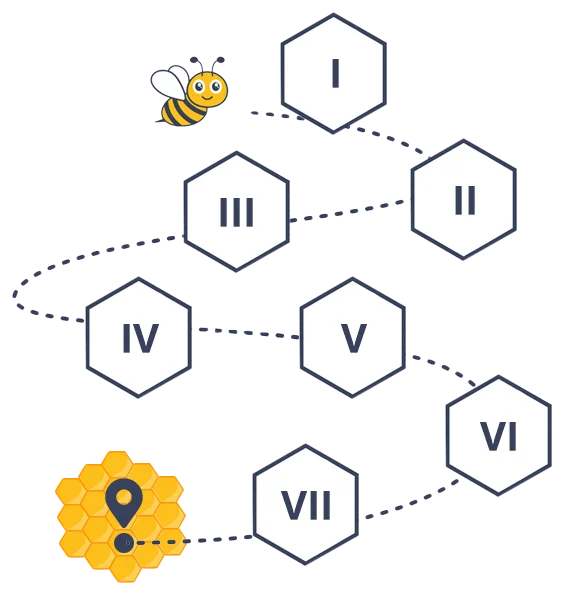

Your process with planning flex

- Workshop-Phase

- Description of the configuration

- System configuration in test run

- Start of the service

- Provision of customer orders

- Import and planning of orders

- Provision of the finished planning

Our offer

Basis Package

- 4 planning runs

per month - Planning for machinery

up to 10 machines* - and more

from 1,500 EUR

plus VAT

Premium package

- 8 planning runs

per month - Planning for machinery

up to 40 machines* - and more

from 3,000 EUR

plus VAT

Enterprise package

- Unlimited planning runs

per month - Unlimited machine orders

per month - and more

on request

* optional: expansion by up to 20 machines possible for a fee

Our team

Michael is the managing director of tetys and the creative mind behind the idea of planning flex. With years of experience in production companies - particularly in the food, mechanical engineering and automotive supply industries - he knows the practical challenges inside out and has built up in-depth knowledge of production and planning processes. Today, he uses his expertise to support companies with innovative solutions such as planning flex and to make their processes more efficient.

Frank is a PPS expert at tetys. He has over 30 years of experience as a production planner in the industry and has already spent almost 20 years enthusiastically planning several sites with FEKOR. He also has in-depth user knowledge of Fekor and is familiar with various production and planning challenges faced by companies and the corresponding solutions in Fekor. Today he works for planning flex as a planner, gives Fekor presentations, user training and supports new customers during the introduction phase.

Petra learnt production planning from the ground up and has gained experience in the pharmaceutical, food and plastics industries with various planning tools. With the PPS system FEKOR, the extremely challenging planning of a very complex food production was no longer a problem. Identifying planning challenges and developing individual solutions with the FEKOR tools is now Petra's job and favourite pastime. At tetys, she passes on her knowledge to customers through consultations, workshops and training courses.